The Mechanical Engineering Program trains students to become technical experts and researchers who are able to provide prosperous living environments in human society. It does so by providing them with the broad range of knowledge and skills they need to adapt to the increasingly diverse science and technology, with a central focus on mechanical engineering, a key field of engineering for manufacturing and craftsmanship (monozukuri).

In addition to ensuring that students are taught in small groups and engage in substantial practical training and laboratory work classes, this program places emphasis on the importance of providing computer education adapted to our advanced information-oriented society and teaching technical English in specialist fields in step with globalization.

All of the research projects conducted by this program also address topics that are real-life, cutting-edge issues in our society, and students have the opportunity to work on such research for their graduation research project in the fourth year or in graduate school.

Fostering engineers and researchers who will create future machines and play an active role globally

Features of the program

Program of education

The Mechanical Engineering Program has adopted nine education and learning goals focused on training the ability to understand and apply basic theory and techniques and developing creativity. In doing so, we aim to train researchers and technical experts who have the potential to pursue careers around the world once they graduate. The key specialist subjects cover areas such as analyzing the strength and structure of various materials from machines to organisms, ascertaining a clear picture of hydrodynamic behavior, converting, transmitting and using heat and other kinds of energy, the mechanics of machinery, methods of analyzing and controlling the vibrations of automobiles and railways, etc., design techniques using mechanical design theory and computers, various processing techniques, various methods of measuring complex forms, methods of designing robots and other control systems, and mechatronics.

This program of education has received accreditation from the Japan Accreditation Board for Engineering Education (JABEE) as a “JABEE accredited program in mechanical engineering.”

Introduction to classes

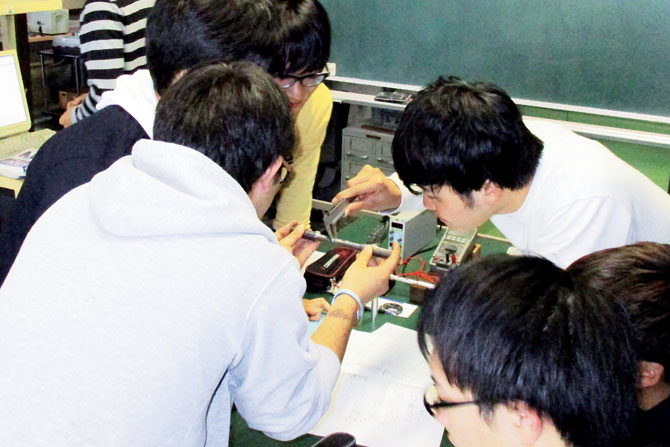

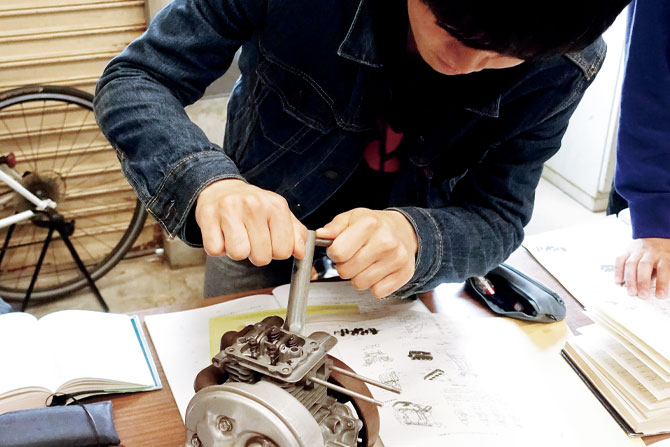

Mechanical Engineering Laboratory WorkⅠ~Ⅳ

Mechanical Engineering Laboratory Work is a one-year practical training course for third year students. The laboratory work allows them to acquire first-hand experience of what they have learned in lectures, in turn deepening their understanding of the phenomena, and allowing them to polish the grasp of engineering that they need to design and produce mechanical systems. The laboratory work covers topics such as experiments on power generation by engines, measuring the temperature of combustion flames, the processing of microelectromechanical system (MEMS) devices that can also be used in smartphones, experiments to stretch and break down metals, and the analysis of the oscillation of springs. In the laboratory work, students have the opportunity to learn from faculty members with expertise in various specialist fields who share with them the knowledge and measurement and analysis techniques that they have cultivated in their research up until that point. Students are also able to acquire the skills they need to pursue their graduation research projects, such as methods of creating drawings and graphs that communicate the results of experiments in easily comprehensible formats and observation methods for appropriately interpreting experiment data and assigning it significance.

Advanced research pursued

by the program

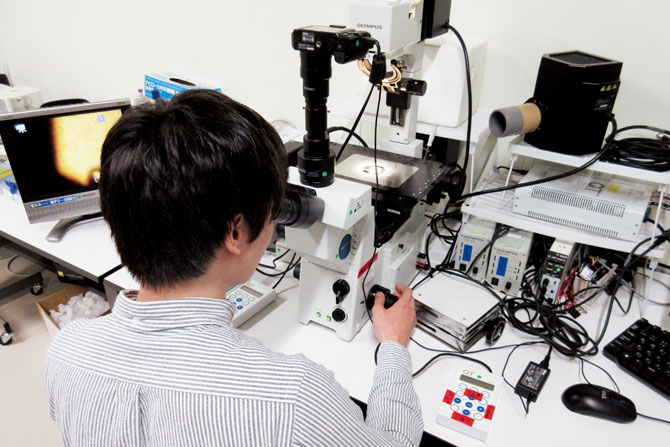

Development of tribological technology in the field of biomechanics

Nitta Isami

The research area of our laboratory is tribology, the purpose of which is to reduce friction and allow smooth machine movement. Reducing friction improves the fuel efficiency of automobiles, which can contribute to the impact on our environment.

Two examples of our research in developing tribological technology in the field of biomechanics can be seen here. Figure 1 shows a spinal fixation system used to correct curved sections of scoliosis. We found that when micro protrusions on the bottom surface of a fastening screw are formed by laser processing the friction coefficient increases, making it possible to obtain a sufficient fixing force even with small tightening torque. This result has contributed to the miniaturization of fixed systems.

Figure 2 shows an osteosynthesis plate used to treat wrist fractures. Since injuries frequently occur in the working age of 40-60, patients often need to quickly return to their lives after treatment. Treatment requires a polyaxial locking screw that can be inserted into the bone at any angle. By applying surface treatment techniques derived from tribology to improve the hardness of the screw surface, we successfully developed a novel locking mechanism for this treatment.

These studies were conducted together with a medical device manufacturer in Niigata prefecture, allowing our students to grow as young engineers while participating in collaborative research.

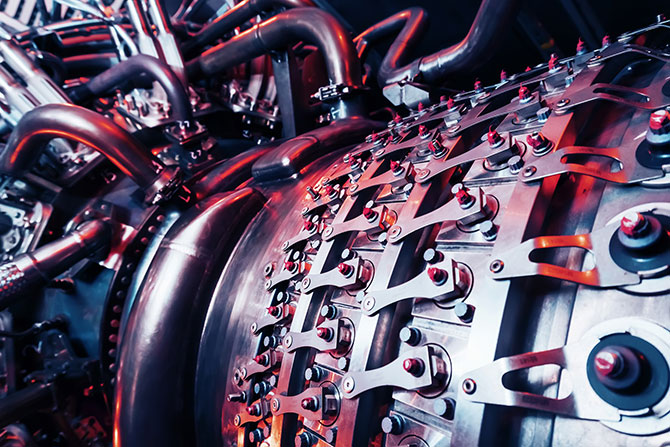

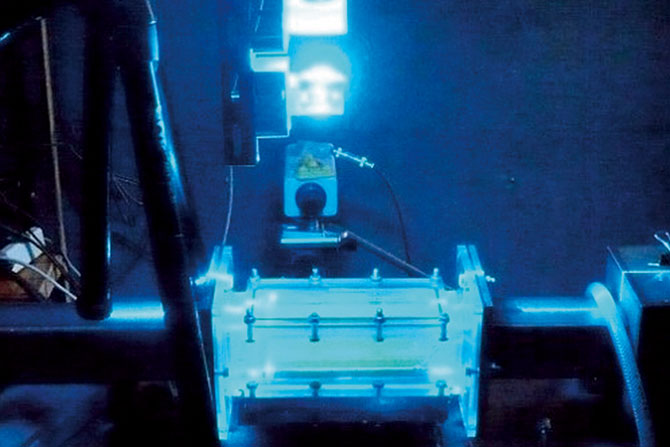

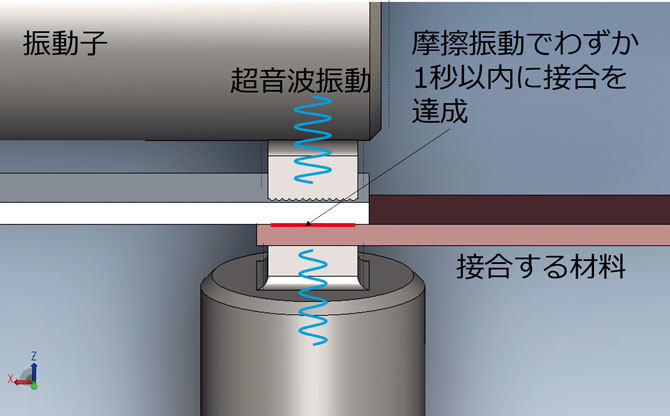

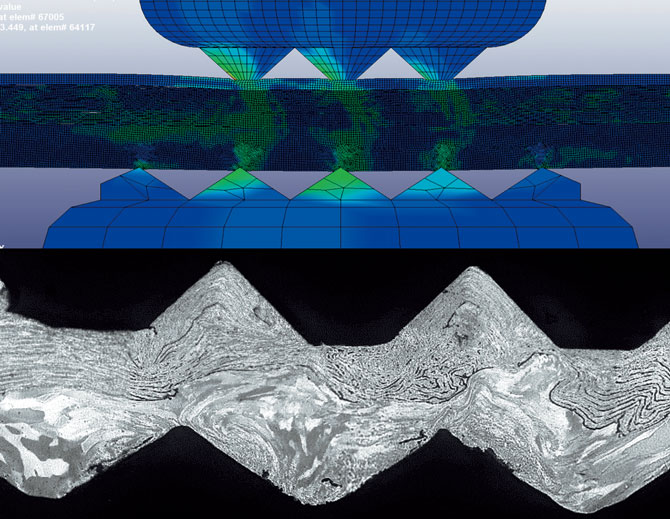

Materials joining technology for multi-materialization.

Materials joining is an essential technology to assemble mechanical products. In recent years, “Multi-materialization” which is a design concept to provide highly functional structures by combining dissimilar materials is of paramount importance in several fields including automotive and aerospace industries. The materials joining is a key technology for the feasibility of multi-materialized design. Ultrasonic bonding is one of promising technologies and is capable of joining the materials in a fraction of a second by rubbing the materials each other at a high frequency. We investigate microscopic phenomena at the bonding interface by utilizing a combination of microstructural analysis, simulation and visualization.

Licenses and qualifications that can be acquired

-

LicensesFirst class upper secondary school teacher's license (industry)

-

QualificationsFirst class chief boiler/turbine engineer’s license (can be acquired with six years practical experience)

Associate professional engineer (JABEE accreditation), etc